The Tintagel Castle Footbridge

Pdf downloadThe Tintagel Castle Footbridge is a testament to modern engineering and architecture. Commissioned by English Heritage and designed by Ney & Partners in collaboration with William Matthews Associates. Conceptual design began in 2016 and construction took place between 2017 and 2019.

This bridge, located in Cornwall, (England) UK, is part of a mythological backdrop. The legend of King Arthur and the Knights of the Round Table has penetrated into European culture, although its historical existence remains a mystery.

Tintagel Castle, the supposed birthplace of King Arthur, is in fact a 13th century Norman ruin, deliberately built in a style evocative of older times. It is this mixture of fact and fiction, of presence and absence, that makes Tintagel such an evocative site.

The design of the bridge had to comply with the client's requests and the requirements imposed by the location:

- The location is not accessible by motor vehicle

- The bridge must blend in perfectly with its surroundings.

- Minimal impact on the site and archaeological remains

- Step-free access

- Do not include anything that would visually conflict with the ruins

Creative process and technical solutions

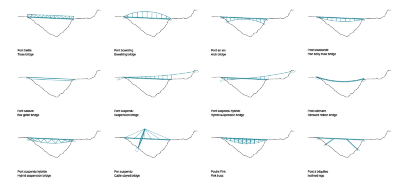

Initially, a catenary bridge was considered for its visual elegance. However, this solution presented technical problems, such as the need for significant elevation (remember that steps could not be used) and inadequate flexibility for a site exposed to high winds.

Different models were considered:

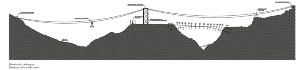

Finally, an isostatic solution was chosen; the footbridge is formed by two independent cantilevers that emerge from the rock surface and extend to almost touch each other in the middle.

The characteristics of the bridge are:

- Bridge width: 2.4 m

- Maximum span: 67 m

- Total length: 67 m

- Total weight: 60 tons

The bridge was built with a cable crane without the need for supports, allowing the construction to advance sequentially into the void from the pillars, without the need for temporary supports.

The use of lightweight materials, such as stainless steel, made it possible to overcome all the limitations we have mentioned. For the construction, 20 tonnes of 2205 duplex stainless steel (UNS S32205) were used along the length of the bridge.